CNC Machines are the greatest invention of industries globally. These machines create beautiful and exact machine components and structural elements.

CNC refers to "Computer Numerical Control." CNC machines are electro-mechanical devices that manipulate machine shop tools employing computer programming inputs. This high-tech technology provides a versatile and automatic means to manufacture large-volume runs of high-quality components. The high levels of precision and repeatability offered by CNC machining techniques make it an optimal tool for most manufacturers.

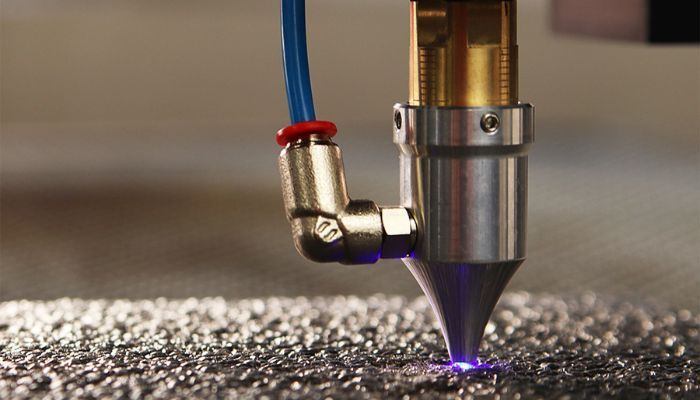

The CNC machine procedure starts with designing the components in CAD software. The 3D model determines the essential dimensions and properties of the resultant part. Some of these programs are available in CAD-CAM packages so that the flow can continue in the same programs. Else, CAD models are fed into designated CAM software. If both CAM and CAD are from the same product family, no translation of files is required. Or else the CAD data need to be imported. The CAM software concocts the model for the whole manufacturing process. First, it checks the model for mistakes. Then it produces a CNC program to manufacture the physical part. The program then guides the cutting head in coordination during the manufacturing process. The third step is picking the correct parameters. These include voltage, cutting speed, voltage, RPMs, etc. The configuration relies on the part's geometry and the available tooling and machinery.

At last, the software regulates the nesting. Nesting means the placement and orientation of components relative to raw material. The goal is to maximize material usage. All this information is then decoded into codes that the machine can comprehend, the M-code and G-code.

CNC machines have proved to be very beneficial for manufacturing industries, and these reasons are enough to prove.

Industries that employ CNC machines can manufacture parts 24/7. The machines may constantly run with little-to-no human involvement. The CNC machines also need less space than the workstations or manual machining setups, so a factory with set square footage can have more devices running simultaneously.

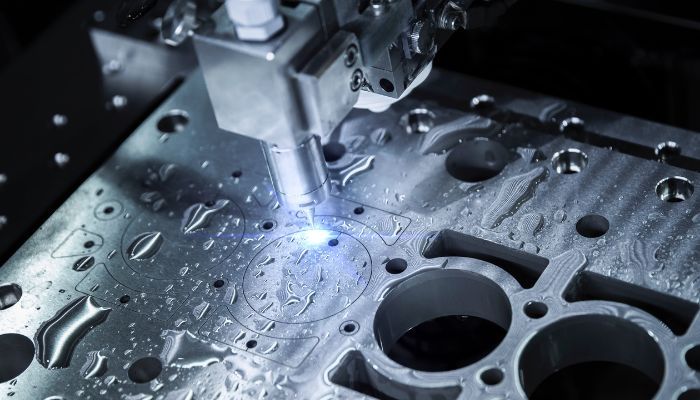

CNC machines use extremely complex programming operations. This technology follows these instructions without letting any unwanted variation or human error. The components manufactured are precise, of high quality, and identical. CNC machining can also manufacture components with intricate, complex designs.

Every CNC machine functions with a CAD design so that the prototyping method will be much faster. The software catches or averts many possible design faults or potential risks with varied materials. When the testing and prototyping processes are shortened, products can go from design to creation faster. CNC machine instructions can also be advanced or replaced quickly, so there is little or no delay between production changes.

Minimalized risks of manufacturing errors and CAD file designs eventually decrease the per-unit cost of production. CNC machines also need less human labor, which further diminishes the product price.

CNC machines' myriad and extraordinary benefits lead to their applications in different sectors, including the following.

CNC machines are highly useful in metal removal sectors such as aerospace industries, automotive industries, and in making Jewellery as well. This technology abolishes excess metal from raw materials to acquire desired end product. CNC machines can also produce shaped developments in the manufacturing sectors, including rounded, threaded, rectangular, square, or even three-dimensional items.

Several industries need thin metal plates, such as steel plates, to manufacture end products. Different metal fabrication tasks, like drilling precision holes, plasma or flame cutting, welding, and shearing, have been made convenient with CNC machines. There are myriad industries for fabricating metals that would take advantage of the CNC machines, for example:

Motherboards and computers have brains with millions of tiny components that must be made accurately.

CNC machines are employed to make barrels, pins, ammunition clips, triggers, and different components of the gun.

The EDM machines engender sparks that burn the undesirable metal away. Through CNC mechanization, EDM machining can be conducted in two ways; Vertical EDM needs an electrode with the same size and shape as the cavity to be carved out, and Wire EDM is employed to make the punch as well as dies combinations for the die set. These are then used in the metal fabrication industries.

CNC machines can even be applied in the electrical industry, woodworking industries, lettering and engraving systems, the pharmaceutical industry, the beverage and food industry, and much more. Whatever manufacturing business you are in, you will undoubtedly find some CNC machine that suits your requirements.