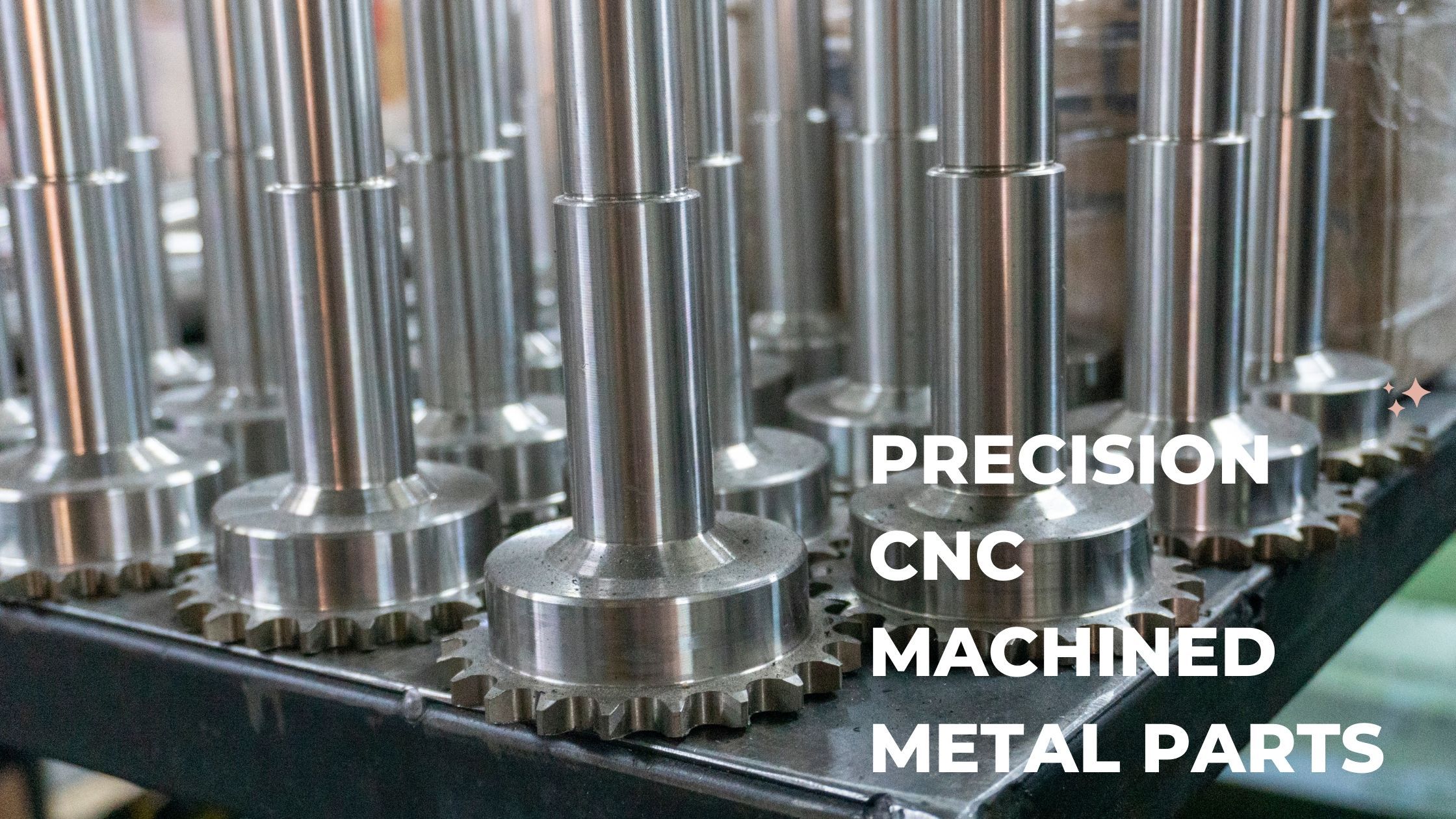

Nowadays, we see a revolution in the industries in the form of the introduction of CNC machining and processes. These types of machining parts have brought a change in the industry in a way that has reduced the amount of time that was usually required to carry out the daily industrial processes. Although CNC machining has become quite popular nowadays, a lot of people are not aware of what exactly CNC machining is, how it works, and the role it plays in facilitating the industries. Let's look at what exactly CNC machine metal parts are. We see that they are the precision machined parts that often need various features and specific functions that are essential in accordance with the application they are planned to be used for. These parts exist in multiple forms. They could be in the form of threads, holes, grooves, tapers, and various other types of products that are supposed to fix with the different types of components.

Precision machining is a type that is usually used to produce the types of CNC machine metal parts that are designed in a way that they fulfill the requirement of that extra precision to make the product function properly. It could be considered by the example of the type of components that are used to make up the engine of an automobile engine. It needs precise specifications to function correctly, providing the best results. There are different types of machines that do not have room for error. They are the type of machines that require specialized types of equipment that are used for the applications that require closer tolerance. When someone uses CNC machines are known as the computer numerically controlled machines that can be in the form of lathes and presses, manufacturing their parts can require a keen level of attention to the details.

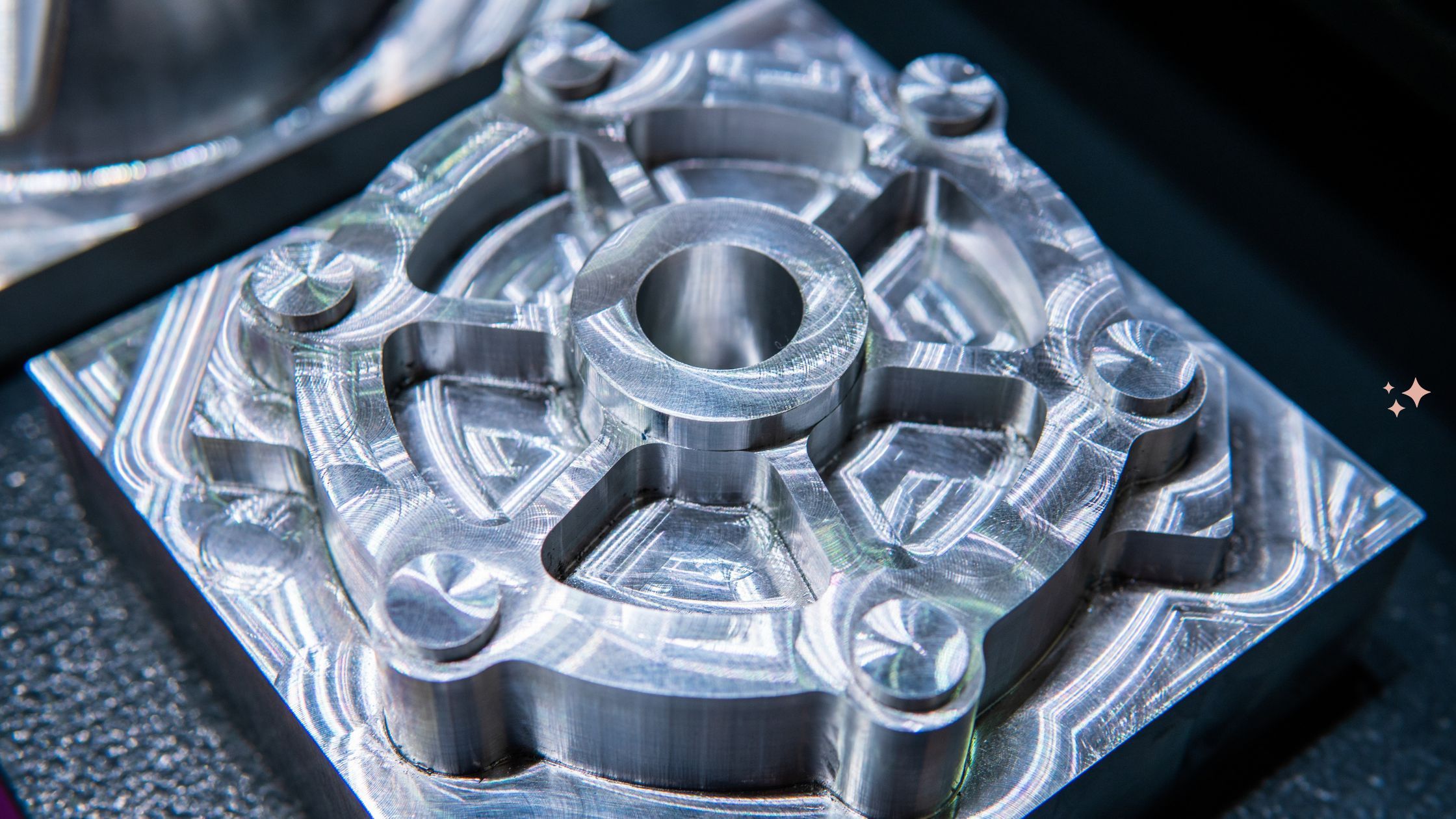

The process of precision machining is the type of process that often starts with an initial sketch. The sketch is made using the computer-based design software that is also known as the CAD software. In the market, the engineers are using various types of CAD software that can be in the form of AutoCAD that is there to create the designs and diagrams that are usually three-dimensional images of a hand-drawn sketch.

The design that has been created is then entered into the computer-aided manufacturing programs or the CNC machines with the help of experts and mechanists. The computer then automates the removal of the material to produce CNC machine metal parts. The precision machining process then allows for more precision and greater accuracy. Each of the cuts is then completed by using the machine that is supposed to receive the instructions with the help of the computer software.

These machines can carry out precise cuttings with a minimal margin of error. This can lead to increased repeatability as one can continue to produce thousands of similar types of parts with the same specifications and tolerance that could be down to 0.01-0.05mm. This is the most important factor that matters in the industries as it can make the process of bulk production easier as one can produce thousands of parts of a similar type with the exact same as the first one even in terms of specifications as well.