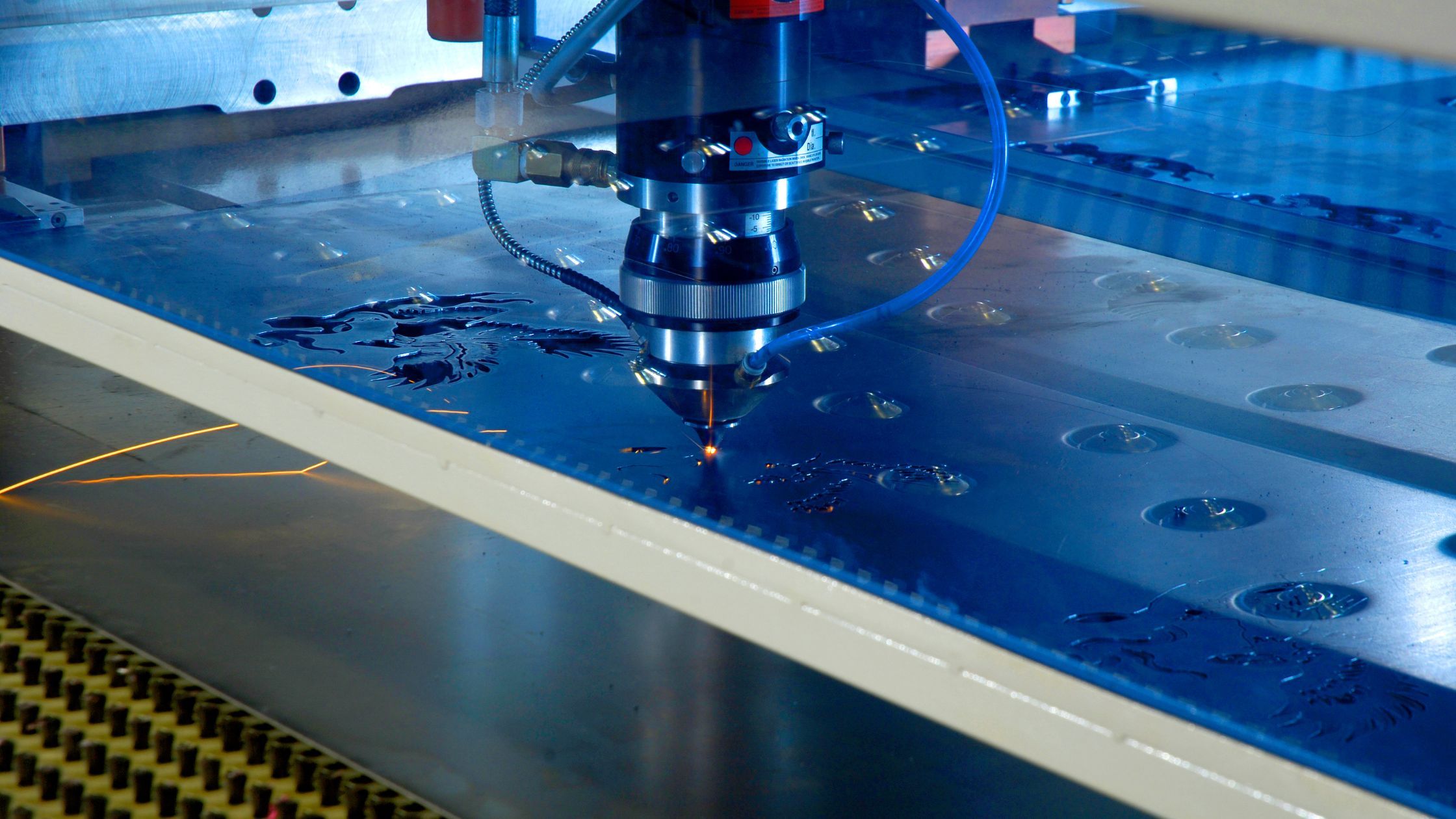

In the CNC machining process, industrial tools and machines are moved by computer software that has been pre-programmed. The method may be used to manage a wide range of complicated machinery, including grinders and lathes, mills, and CNC routers. Three-dimensional cutting jobs may be completed with CNC machining in a single set of instructions.

The CNC method operates in opposition to and thereby overcomes the constraints of manual control, in which live operators are required to prompt and lead milling tool orders via levers, buttons, and wheels. A CNC system may appear to be a standard set of computer components to the untrained eye, but the software programs and consoles used in CNC machining separate it from all other kinds of computation.

Machines in CNC production are controlled numerically, using a software program assigned to control an object. The language used in CNC machining is known as G-code. It is created to manage the many characteristics of a corresponding machine, such as speed, feed rate, and synchronizing machining. In essence, It allows you to pre-program the speed and location of machine tool functions and then execute them through software in regular, predictable cycles with minimum input from human operators. A 2D or 3D CAD drawing is created during the CNC machining process, which is subsequently converted into computer code for the CNC system to execute. After entering the software, the operator runs it to check that there are no code errors.

CNC routers have revolutionized how many individuals and companies produce their creativity and goods by enhancing efficiency beyond previously unattainable levels. But what exactly is a CNC router, and how does it operate? Here's an overview of CNC routers to help you grasp the basic mechanics that power them.

CNC routers are equipment used to cut various materials, including wood, plastic, metal, and high-density foam. CNC means computer numerical control, and it refers to machines that are operated by computer software and electronics rather than a direct human operator.

CNC machines can often cut in three directions, known as the X, Y, and Z axes. The X-axis runs from front to back and is generally the longest. The Y-axis represents the left and right directions, while the Z-axis represents the up and down directions. CNC routers are quicker and more exact than people since they operate on computers, making them valuable in production.

If you're new to CNC machining, you've undoubtedly noticed how much new terminology comes with the job. Experienced operators would use language like "high-rail moving gantry" or "tangential oscillating knife" as if they were common jargon. So, when you hear about machines having three, four, or five axes, you may ask what the difference is. And how many do I require?

Diversified Machine Systems (DMS) manufactures 3- and 5-axis machines to exact specifications for our customers. When guiding clients through CNC alternatives, we evaluate three dimensions and what each entails:

3-axis routers are the most basic CNC equipment, yet they are also incredibly competent and versatile. They function on three axes, as the name implies: The X-axis, which travels left to right; the Y-axis, which goes front to back; and the Z-axis, which moves up and down. While a 3-axis machine cannot create 3D patterns, it is more than capable of making incredibly intricate and exact 2D designs. Three-axis machines are commonly used in applications that require milling on only one side of a workpiece. While it is still feasible to process the workpiece on all sides using stops to move it, this can be time-consuming and costly. 3-axis machines are widely used in the woodworking, sign-making, marine, and even aerospace sectors.

Don't underestimate the capabilities of a 3-axis machine; it may be able to solve your production problems. DMS provides several adjustments to handle various applications, including automated lubrication, different table choices, vacuum options, and configurable stroke sizes, to mention a few. These features make these machines extremely adaptable and capable of handling a wide range of materials.

Four axes of action are required for processing that involves routing on the sides of an item. The A-axis is a different axis that relates to rotation around the X-axis. This can be accomplished by rotating the workpiece or, more typically, by rotating the spindle around the workpiece. By adding an A-axis, a milling machine may also function as a CNC lathe.

For some applications, the extra expense of a 4-axis machine is worth considering. By lowering the number of fixtures required by a 3-axis machine, the A-axis can save you money. It can also reduce time and boost production by eliminating pauses to reposition the workpiece using a 3-axis router to cut on more than one side of an item. The ability to cut or drill a workpiece's sides enables more intricate curves and helical machining, making it perfect for cylindrical surface applications. In the aerospace, automotive, and mold-making sectors, 4-axis machines are popular. With many of the same modifications as 3-axis machines, they may be configured to handle a wide range of materials and applications.

Exporters of 5-axis CNC routers use the same X, Y, and Z axes as 3-axis routers but add two more. They can revolve around the X-axis with the A-axis, just like 4-axis machines. They may also revolve around the Y-axis with the B-axis and around the Z-axis with the C-axis. 5-axis machines may work on both the A- and C-axes or both the B- and C-axes at the same time. These axes, like 4-axis machines, can be accomplished by rotating the workpiece or the spindle. When contemplating milling on a 4-axis machine, consider the additional benefits of a 5-axis machine. In reality, for some complicated forms, a 5-axis is required rather than an option.

5-axis machines can manufacture exceedingly complex 3D objects and are extremely versatile in their applications. This makes them incredibly popular in almost every area, including prototyping, energy, construction, and military, to mention a few. Continuous C-axis rotation, barcode scanners, automated lubrication, and tool changers are examples of customizations. The options are limitless.

We hope this helps you determine what sort of machine you will require for your unique production scenario. Beyond the basic setup, Z-stroke size, and table size, there are practically unlimited tweaks and permutations to explore.